| Items |

SH(W)-1025B(M)-70S(D)

4 Ampere (A) Maximum Inrush Current and 120 to 120 Volt (V) Rated Voltage SH-Type Positive Temperature Coefficient (PTC) Air Heater

|

SH(W)-1030B(M)-70S(D)

5 Ampere (A) Maximum Inrush Current and 120 to 120 Volt (V) Rated Voltage SH-Type Positive Temperature Coefficient (PTC) Air Heater

|

SH(W)-1040M(B)-70S(D)

7 Ampere (A) Maximum Inrush Current and 120 to 120 Volt (V) Rated Voltage SH-Type Positive Temperature Coefficient (PTC) Air Heater

|

SH(W)-1050M(B)-70S(D)

8 Ampere (A) Maximum Inrush Current and 120 to 120 Volt (V) Rated Voltage SH-Type Positive Temperature Coefficient (PTC) Air Heater

|

SH(W)-1060M(B)-70S(D)

10 Ampere (A) Maximum Inrush Current and 120 to 120 Volt (V) Rated Voltage SH-Type Positive Temperature Coefficient (PTC) Air Heater

|

|

Description

|

N/A

PTC has a unique heat property that allows the PTC heat output to be regulated by the airflow applied. The higher the airflow, the higher the heat output and power (wattage). Therefore, depending on the end design, if the ambient temperature is high, the PTC output power will decrease; if the airflow is high with low ambient temperature, then the PTC output power will increase.

|

|

Brands

|

N/A

Pelonis Technologies

|

|

Type

|

N/A

Wired

|

N/A

Wired

|

N/A

Terminal

|

N/A

Terminal

|

N/A

Terminal

|

|

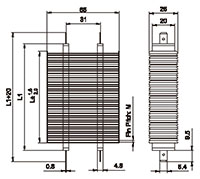

Length (L)

|

N/A

70 mm

|

|

Length (L1)

|

N/A

84 mm

|

|

Maximum Power

|

N/A

|

|

Tolerance for Maximum Power

|

N/A

|

|

Rated Voltage

|

N/A

120 V

|

|

Maximum Voltage

|

N/A

135 V

|

|

Maximum Inrush Current

|

N/A

4 A

|

N/A

5 A

|

N/A

7 A

|

N/A

8 A

|

N/A

10 A

|

|

Air Speed

|

N/A

6.4 m/s

|

|

Power at 6.4 Meter Per Second (m/s) Air Speed and 20 Degree (º) Celsius Temperature

|

N/A

250 Watts

|

N/A

300 Watts

|

N/A

400 Watts

|

N/A

500 Watts

|

N/A

600 Watts

|

|

Tolerance for Power at 6.4 Meter Per Second (m/s) Air Speed and 20 Degree (º) Celsius Temperature (±)

|

N/A

10 %

|

|

Power at 6.4 Meter Per Second (m/s) Air Speed and 0 Degree (º) Celsius Temperature

|

N/A

275 Watts

|

N/A

350 Watts

|

N/A

450 Watts

|

N/A

550 Watts

|

N/A

675 Watts

|

|

Tolerance for Power at 6.4 Meter Per Second (m/s) Air Speed and 0 Degree (º) Celsius Temperature (±)

|

N/A

10 %

|

N/A

10 %

|

N/A

10 %

|

N/A

10 %

|

N/A

7 %

|

|

Available Frames

|

N/A

MSHF MSHF-70

|

|

Industry Standards/Certifications

|

N/A

CE Recognized Reach Compliant CRU®US Recognized CSA Restriction of Hazardous Substances (RoHS) Compliant Underwriters Laboratories (UL)

|

|

Fin Pitch

|

N/A

2.6 mm

|

N/A

2.6 mm

|

N/A

1.68 mm

|

N/A

1.68 mm

|

N/A

1.68 mm

|

|

Voltage

|

N/A

Both AC/DC available. Please refer to Part Numbering for voltage ranges (for automotive use 12V˜520V).

|

|

Power

|

N/A

50˜2000 Watts

|

|

Exemptions

|

N/A

Our PTC elements contain Pb under RoHS exemption 7(c)-I : Electrical and electronic components containing lead in a glass or ceramic other than dielectric ceramic in capacitors, e.g. piezoelectronic devices, or in a glass or ceramic matrix compound.

|

|

Intended Application

|

N/A

Air

|

|

Width

|

N/A

65 mm

|

|

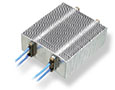

Power In

|

N/A

Single sided Positive (+) and negative (-) inputs

|

N/A

Single sided Positive (+) and negative (-) inputs

|

N/A

Positive (+) and negative (-) inputs on either side

|

N/A

Positive (+) and negative (-) inputs on either side

|

N/A

Positive (+) and negative (-) inputs on either side

|

|

Wiring

|

N/A

Can be connected to power directly

Require customization

|

N/A

Can be connected to power directly

Require customization

|

N/A

Wires with female terminals required

Options: single-stage/multi-stages power setting wiring

|

N/A

Wires with female terminals required

Options: single-stage/multi-stages power setting wiring

|

N/A

Wires with female terminals required

Options: single-stage/multi-stages power setting wiring

|

|

Standard Frames

|

N/A

Available

|

|

Accessories

|

N/A

|

N/A

|

N/A

Available

|

N/A

Available

|

N/A

Available

|

|

Limitations

|

N/A

≤15 A≤1800 Watts

|

N/A

≤15 A≤1800 Watts

|

N/A

No current and power (W) limitations

|

N/A

No current and power (W) limitations

|

N/A

No current and power (W) limitations

|

|

Suitable Applications

|

N/A

- Most suitable for applications where power connection is fixed on a single side.

- Better vibration endurance for automotive. Prevents loose connection or poor contact between terminals. Reduces the possibility of oxidation of connection points between male and female terminals causing increase in resistance leading to overheated joints and vibration failure.

- Additional silicon seal can be added for applications located in high humidity environments. Effectively increases the life-span of the PTC.

|

N/A

- Most suitable for applications where power connection is fixed on a single side.

- Better vibration endurance for automotive. Prevents loose connection or poor contact between terminals. Reduces the possibility of oxidation of connection points between male and female terminals causing increase in resistance leading to overheated joints and vibration failure.

- Additional silicon seal can be added for applications located in high humidity environments. Effectively increases the life-span of the PTC.

|

N/A

- Most suitable for standard applications where power connection is not limited to a single side.

- Vast scope of heating applications.

|

N/A

- Most suitable for standard applications where power connection is not limited to a single side.

- Vast scope of heating applications.

|

N/A

- Most suitable for standard applications where power connection is not limited to a single side.

- Vast scope of heating applications.

|

|

Heater Type

|

N/A

Positive Temperature Coefficient (PTC)

|

|

Thickness

|

N/A

26 mm

|

|

Special Length (L)

|

N/A

225 mm268 mm314 mm358 mm403 mm446 mm492 mm

|

|

Number of Tubes

|

N/A

3

|

|

Fin Width

|

N/A

65 mm

|

|

Overview

|

N/A

Pelonis Technologies' innovative Fin PTC Air Heaters are significantly more efficient than coil or conventional heaters and create a very effective heat transfer in a small space.

|

|

Positive Temperature Coefficient (PTC) Characteristics

|

N/A

Fin PTC Air Heaters have self-regulating characteristics and will not overheat. This results in better conductivity, greater operating efficiency, a stable electronic response, and longer life expectancy.

|

|

Innovative Features

|

N/A

- Available designs include very low air resistance and high heating efficiency.

- Internal safety-fuse protection; auto-cut-off to prevent abnormal high current or other external factors causing safety concerns.

- Fast thermal response time and low inrush current; will not cause sparks or flame by instant/sudden power supply variations or when in contact with flammable objects including matches, cotton, paper, etc.

- Designed with single or double insulation; when in contact with metallic objects, will not cause electric shock or short circuit.

- Double insulated PTC can be used underwater without causing electricity leakage or short circuit (customized).

- Allows for independent control of single PTC (500W, 800W), double PTC (1000W, 1500W) or triple PTC (1500W, 2000W) heating tubes; reduces electricity cost and extends product life.

- The poles and terminals are connected by point welding, thereby preventing the electrodes from loosening and causing resistance and temperature to increase due to cold contraction or heat inflation.

- The heating components are tightly sealed and the electrodes are unexposed which makes Fin PTC Air Heaters suitable for applications in bathrooms or high humidity environments.

- Long service life; do not crack, burst, or burn even when heated under no airflow conditions.

- No moving parts to wear out.

- Voltage change does not affect its current and output power (insensitive to unstable voltage).

- The surface temperature of the PTC pellets does not change while power regulates with ambient temperature and heat dissipation rate. Therefore, the higher the environmental temperature, the greater the power efficiency.

- Heating power (W) and self-regulating function is in correlation to the heat dissipation rate.

|

|

Added Protection

|

N/A

The internal heating elements are fully cladded in a sturdy aluminum structure in order to reduce exposure to air and to withstand high levels of humidity and vibration. This method of protection also prevents loosening of the individual heating pellets and eliminates oxidation which can lead to eventual power reduction and shorter life expectancy.

|

|

Customized Solutions

|

N/A

Fin PTC Air Heaters can be supplied in various sizes based on customer requirements and can also be configured with outer frames, thermostats, fuses, axial cooling fans, and protective shields to provide a complete single source assembly solution.

|

|

Additional Information

|

N/A

Standard Fin PTC Air Heaters are designed with single stage heating (full power). However, SH type Fin PTC Air Heaters can be designed with multiple power stages by heating one or two tubes at a time. This makes them more economical through power saving and will also help extend heater life expectancy. If multiple stage heating is required in an application design, please contact our Sales Representatives in advance for special design and wiring.

|

|

Applications

|

N/A

Fin PTC Air Heaters can be used in automotive (electric vehicles) and other applications for heating, dehumidifying, and thermal retention or in general electronic appliances including hand dryers, air conditioners, irons, laminating machines, and adhesive sealing machines. Additional applications include freeze protection of outdoor surveillance cameras, 3C products, and other electronic devices.

|

|

Voltage Selection

|

N/A

- Standard voltages: 100V~120V and 200V~240V

- For all other voltage range requirements, please contact us for additional information.

|

|

Application Note for Voltage Selection

|

N/A

- Under constant airflow, increase in voltage will have little effect on the heater power.

|

|

Positive Temperature Coefficient (PTC) Power (W) and Air Flow/Air Speed Considerations

|

N/A

- High air speed is correlated with high heat dissipation rate which results in higher power and a more rapid increase of the surrounding temperature.

- Under low air speed, heater power will decrease, however the temperature at the air outlet will be high.

- Under no airflow, the surface of the PTC fins will approach Curie temperature. The heater power may drop to 1/20 of normal power (at air speed of 6.4 m/s) and stabilizes at a constant temperature.

|

|

Application Note for Positive Temperature Coefficient (PTC) Power (W) and Air Flow/Air Speed Considerations

|

N/A

- The power of PTC heaters is related to the ambient thermal condition and the heat dissipation rate of the heater. When the ambient temperature is significantly higher than the reference temperature or when heat transfer is restricted, the resistance of the PTC will rise rapidly and power consumption reduces. Hence, the higher the heat dissipation, the higher the output power.

- The surface temperature of PTC is self regulated. The lower the surface temperature, the lower the power.

- The MH and MSH type Fin PTC Air Heaters allow three stage temperature settings (high, medium, low). The PTC heater tubes can be controlled independently (please see the "Installation" section for circuit connection), effectively reducing electricity cost and increasing product life. If this function is used in conjunction with air speed adjustment (fans), it will allow more flexibility in the adjustment of air flow and temperature.

|

|

Positive Temperature Coefficient (PTC) Fin Pitch Selection

|

N/A

- Unique Fin PTC pitch range provides a diverse choice of high efficiency vs low air resistance (lower noise level). Choices from 1.2 mm to 2.6 mm are available for various application selections.

- Ultra-high-heating-efficiency Fin Pitch: 1.2 mm (S), 1.68 mm (M) Larger heat dissipation area; higher output power; higher temperature at the air outlet.

- Ultra-low-air resistance (lower noise level) Fin Pitch: 2.0 mm (N), 2.6 mm (B) Less heat dissipation area; projects heat further; lower output power.

- The Power (W) in the Specifications tables is based on Fin PTC Air Heaters with extra-high efficiency fin pitches. Fin pitch 1.68 mm (M) for MSH, SH and OH models, and fin pitch 1.2 mm (S) for MH model.

- The Power (W) of Fin PTC Air Heater with fin pitch 2.0 mm (N) is 95% of Fin PTC Air Heater with fin pitch 1.2 mm (S).

- The Power (W) of Fin PTC Air Heater with fin pitch 2.6 mm (B) is 90% of Fin PTC Air Heater with fin pitch 1.2 mm (S).

- The Power (W) of PFin PTC Air Heater with fin pitch 2.6 mm (B) is 90% of Fin PTC Air Heater with fin pitch 1.68 mm (M).

|

|

Positive Temperature Coefficient (PTC) Insulation Consideration (Doubled Insulation - Electrically Insulated Heater)

|

N/A

- The Power (W) in the "Standard" tables is based on Fin PTC Air Heaters with Single Insulation (S).

- The Power (W) of Fin PTC Air Heaters with double insulation (D) is approximately 10% less than Fin PTC Air Heater with single insulation (S).

- The price of Fin PTC Air Heaters with double insulation (D) is 15~30% more than single insulation (S) Fin PTC Air Heaters.

- Double insulated Fin PTC Air Heaters are designed for use where heater exterior (fins) needs to be electrically insulated.

- Both single insulated and glued typed Fin PTC Air Heaters are not electrically insulated on the heater exterior/fins, hence carrying input voltage.

- The Fin PTC heating elements of double insulated Fin PTC Air Heaters are completely insulated within the aluminum tubes, allowing complete electric insulation on the heater exterior (fins).

|

|

Application Note for Positive Temperature Coefficient (PTC) Insulation Consideration (Doubled Insulation - Electrically Insulated Heater)

|

N/A

- The fins on Fin PTC Air Heaters with Double Insulation (D) are electrically insulated. This is suitable for applications where the device may be in contact with other conductive materials (eg. metal); expose to high humidity; with shock resistance requirement; or in products that require superior stability and quality (eg. automobiles).

- Due to its high safety and reliability performance, double insulated Fin PTC Air Heaters are mainly used by automobiles, electric vehicles, in large-power house heaters such as cold/warm air-conditioners, fan heaters, disinfecting cabinets, dryers and many more.

|

|

Note

|

N/A

- The Power (W) in the Specifications table is based on Fin PTC Air Heaters with Single Insulation (S) and fin pitch of 1.68 mm (M) or 2.6 mm (B). The Power (W) of Fin PTC Air Heaters with fin pitch 2.6 mm (B) is 90% of Fin PTC Air Heaters with fin pitch 1.68 mm (M). Please refer to Notes on Part Numbering for the difference in Power (W) efficiency for each fin pitch type and insulation type.

- Customized wattage, length and specifications can also be designed for large quantities.

|

N/A

- The Power (W) in the Specifications table is based on Fin PTC Air Heaters with Single Insulation (S) and fin pitch of 1.68 mm (M) or 2.6 mm (B). The Power (W) of Fin PTC Air Heaters with fin pitch 2.6 mm (B) is 90% of Fin PTC Air Heaters with fin pitch 1.68 mm (M). Please refer to Notes on Part Numbering for the difference in Power (W) efficiency for each fin pitch type and insulation type.

- Customized wattage, length and specifications can also be designed for large quantities.

|

N/A

- This is a standard model. The delivery time for these model is shorter and may have a lower cost.

- The Power (W) in the Specifications table is based on Fin PTC Air Heaters with Single Insulation (S) and fin pitch of 1.68 mm (M) or 2.6 mm (B). The Power (W) of Fin PTC Air Heaters with fin pitch 2.6 mm (B) is 90% of Fin PTC Air Heaters with fin pitch 1.68 mm (M). Please refer to Notes on Part Numbering for the difference in Power (W) efficiency for each fin pitch type and insulation type.

- Customized wattage, length and specifications can also be designed for large quantities.

|

N/A

- This is a standard model. The delivery time for these model is shorter and may have a lower cost.

- The Power (W) in the Specifications table is based on Fin PTC Air Heaters with Single Insulation (S) and fin pitch of 1.68 mm (M) or 2.6 mm (B). The Power (W) of Fin PTC Air Heaters with fin pitch 2.6 mm (B) is 90% of Fin PTC Air Heaters with fin pitch 1.68 mm (M). Please refer to Notes on Part Numbering for the difference in Power (W) efficiency for each fin pitch type and insulation type.

- Customized wattage, length and specifications can also be designed for large quantities.

|

N/A

- This is a standard model. The delivery time for these model is shorter and may have a lower cost.

- The Power (W) in the Specifications table is based on Fin PTC Air Heaters with Single Insulation (S) and fin pitch of 1.68 mm (M) or 2.6 mm (B). The Power (W) of Fin PTC Air Heaters with fin pitch 2.6 mm (B) is 90% of Fin PTC Air Heaters with fin pitch 1.68 mm (M). Please refer to Notes on Part Numbering for the difference in Power (W) efficiency for each fin pitch type and insulation type.

- Customized wattage, length and specifications can also be designed for large quantities.

|