| Items |

KC02-2060a

KC Series Ultra-High Temperature Ceramic Immersion Heater

|

KC02-2060-1

KC Series Ultra-High Temperature Ceramic Immersion Heater

|

KC02-1060

KC Series Ultra-High Temperature Ceramic Immersion Heater

|

KC02-2060-2

KC Series Ultra-High Temperature Ceramic Immersion Heater

|

|

Features & Benefits

|

N/A

Effective & efficient thermal heating

Can be used in air or water

High durability; able to withstand high temperatures (up to 1200ºC when heating in a dry condition)

Very good insulation characteristic; electric leakage is <10mA even when broken

High withstanding voltage; will not break even when 2500V is applied for 1 minute

High watt density; in water <70W/cm2, in air <25W/cm2

Corrosion resistance to aggressive fluids like acid and bases

Very low to no buildup of water heater scale deposits

Quick heat transmission. Air heating surface temperature can reach 1200ºC in 40 seconds; water heating can reach 98% thermal efficiency.

Small yet high powered; high design flexibility

High safety characteristics

Long service life

|

|

Series

|

N/A

KC02

|

|

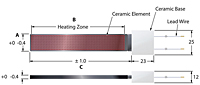

A

|

N/A

17 mm

|

|

B

|

N/A

80 mm

|

|

C

|

N/A

106 mm

|

|

Thickness

|

N/A

4 mm

|

|

Rated Voltage

|

N/A

110 V

|

N/A

110 V

|

N/A

110 V

|

N/A

220 V

|

|

Rated Power in Water

|

N/A

210 Watts

|

N/A

420 Watts

|

N/A

1500 Watts

|

N/A

1500 Watts

|

|

Rated Power in Air

|

N/A

100 Watts

|

N/A

200 Watts

|

N/A

600 Watts

|

N/A

600 Watts

|

|

Ref Temp in Air

|

N/A

400 ºC

|

N/A

630 ºC

|

N/A

1200 ºC

|

N/A

1200 ºC

|

|

Withstanding Voltage (V)

|

N/A

Under room temperature, can apply 2500V/50Hz for 1 minute without damage

|

|

Current leakage under-water

|

N/A

Damaged (broken) = 10 mA Normal condition = 0.025 mA

|

|

Acid Corrosion Resistance

|

N/A

5% when boiled in sulfuric acid solution for 6 hours; corrosion rate <10g/m2.hr

|

|

Alkali Corrosion Resistance

|

N/A

30% when boiled in sodium hydroxide solution for 6 hours; corrosion rate <0.6g/

|

|

Thermal Conductivity (W/m.k)

|

N/A

23-25W.(M.K)-1

|

|

Coefficient of Thermal Expansion ×10-6/ºC (0~1400ºC)

|

N/A

3.1 ×10-6/ºC

|

|

Hardness (HRA)

|

N/A

92.0~94.0

|

|

Additional Information

|

N/A

Ultra-High Temperature Ceramic Heaters have similar characteristic to PTC heaters. As the Power (W) of the heater will vary depending

on the heat dissipation rate, the Rated Power (W) specified in the the product tables is for reference only and will vary

with different applications and ambient environments.

|

|

Installation Guide

|

N/A

ULTRA-HIGH TEMPERATURE CERAMIC IMMERSION HEATERS CAN BE USED BOTH IN AIR OR

UNDER WATER. WHEN USED IN AIR, THE MAXIMUM POWER IS 600W. POWER ABOVE 600W CAN

ONLY BE USED IN WATER WITH THE FOLLOWING GUIDELINES WHICH MUST BE FOLLOWED:

- Ensure heating element is entirely immersed in liquid. If partially exposed in air, it will cause breakage.

- When water has evaporated (dry heating), please do not add water immediately. This may cause cracks or damage to the product.

- Ensure that no glue is adhered to the surface of the product.

- Make sure that the correct voltage is applied.

- Ensure that the heating element is installed vertically. To ensure that the performance and reliability of

the heating element is maximized, install the heating element vertically at the bottom of the container if

used in an instant water heater application. The hot water outlet should be located at the top of the

container. Ensure that the water level is 30~40mm above the heating element.

- To prevent decrease of withstanding voltage of the heating element under severe ambient conditions,

add a thermal resistance rubber seal to the exposed section of the heating element.

|

|

Common Applications

|

N/A

IN WATER:

- Spa Equipment

- Semi-storage type electric water heaters

- Solar heater supports

- Instantaneous hot water heaters

- Packaging machinery

- Central heating systems

IN AIR:

- Motor vehicle cold-start or warmup devices

- Die heating furnaces

- Steam generators

|