| Items |

SD47-4-P0

Servobox Series Model SD47 1-Stage, 4 Ratio, Standard Output Bearing, and P0 Backlash Class Planetary Reducer Gearbox

|

SD47-4-P1

Servobox Series Model SD47 1-Stage, 4 Ratio, Standard Output Bearing, and P1 Backlash Class Planetary Reducer Gearbox

|

SD47-4-P2

Servobox Series Model SD47 1-Stage, 4 Ratio, Standard Output Bearing, and P2 Backlash Class Planetary Reducer Gearbox

|

SD47-5-P0

Servobox Series Model SD47 1-Stage, 5 Ratio, Standard Output Bearing, and P0 Backlash Class Planetary Reducer Gearbox

|

SD47-5-P1

Servobox Series Model SD47 1-Stage, 5 Ratio, Standard Output Bearing, and P1 Backlash Class Planetary Reducer Gearbox

|

|

Description

|

N/A

Quiet Operation

Helical gears reduce vibration and noise.

High Precision

Backlash ≤ 3 arc·min reaches precision alignment.

High Rigidity and Torque

High rigidity and high torque are achieved by integrant needle roller bearings and a one-piece construction.

|

|

Brands

|

N/A

Pelonis Technologies

|

|

Model

|

N/A

47

|

|

Ratio

|

N/A

4

|

N/A

4

|

N/A

4

|

N/A

5

|

N/A

5

|

|

Output Bearing

|

N/A

Standard (Ball Bearing)

|

|

Backlash Class

|

N/A

P0

|

N/A

P1

|

N/A

P2

|

N/A

P0

|

N/A

P1

|

|

Stage

|

N/A

1-Stage

|

|

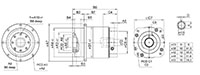

Dimension A1

|

N/A

67 mm

|

|

Number of Holes (A2)

|

N/A

8

|

|

Dimension A2

|

N/A

3.4 mm

|

|

Dimension A3

|

N/A

28 mm

|

|

Dimension A4

|

N/A

47 mm

|

|

Dimension A5

|

N/A

5 mm

|

|

Dimension A6

|

N/A

12 mm

|

|

Dimension A7

|

N/A

72 mm

|

|

Dimension A8

|

N/A

20 mm

|

|

Number of Holes (A9)

|

N/A

4

|

|

Dimension A9

|

N/A

M3 x P0.5

|

|

Dimension A10

|

N/A

3 mm

|

|

Dimension B1

|

N/A

59 mm

|

|

Dimension B2

|

N/A

19.5 mm

|

|

Dimension B3

|

N/A

5 mm

|

|

Dimension B4

|

N/A

3 mm

|

|

Dimension B5

|

N/A

5 mm

|

|

Dimension B6

|

N/A

6.5 mm

|

|

Dimension B7

|

N/A

4 mm

|

|

Dimension B8

|

N/A

4 mm

|

|

Dimension B9

|

N/A

74.7 mm

|

|

Dimension C1

|

N/A

46 mm60 mm63 mm

|

|

Dimension C2

|

N/A

M3 M4 M5

|

|

Dimension C3

|

N/A

8 mm11 mm

|

|

Dimension C4

|

N/A

32 mm

|

|

Dimension C5

|

N/A

30 mm40 mm50 mm

|

|

Dimension C6

|

N/A

M4 x P0.7

|

|

Dimension C7

|

N/A

46 mm55 mm

|

|

Output Frame Dimension A1

|

N/A

12 mm

|

|

Output Frame Dimension A2

|

N/A

20 mm

|

|

Output Frame Dimension A3

|

N/A

28 mm

|

|

Output Frame Dimension A4

|

N/A

47 mm

|

|

Output Frame Dimension A5

|

N/A

67 mm

|

|

Output Frame Dimension B6

|

N/A

M3 x P0.5

|

|

Output Frame Dimension B8

|

N/A

3 mm

|

|

Output Frame Dimension B9

|

N/A

3.4 mm

|

|

Rated Output Torque (Nominal Output Torque) (T2N)

|

N/A

22 N·m

|

N/A

22 N·m

|

N/A

22 N·m

|

N/A

20 N·m

|

N/A

20 N·m

|

|

Maximum Acceleration Torque (T2B)

|

N/A

1.8 Times of Rated Output Torque

|

|

Maximum Output Torque (Emergency Stop Torque) (T2NOT)

|

N/A

3 Times of Rated Output Torque

|

|

Rated Input Speed (n1N)

|

N/A

3000 rpm

|

|

Maximum Input Speed (n1B)

|

N/A

6000 rpm

|

|

Backlash

|

N/A

≤ 3 arc·min

|

N/A

≤ 5 arc·min

|

N/A

≤ 7 arc·min

|

N/A

≤ 3 arc·min

|

N/A

≤ 5 arc·min

|

|

Torsional Rigidity

|

N/A

6 N·m/arc·min

|

|

Maximum Radial Force (Ball Bearing) (n2rB)

|

N/A

2040 N

|

|

Maximum Axial Force (Ball Bearing) (n2aB)

|

N/A

1020 N

|

|

Maximum Radial Force (Taper Bearing) (F2rB)

|

N/A

|

|

Maximum Axial Force (Taper Bearing) (F2aB)

|

N/A

|

|

S5 Cycle Operation Service Life (LH)

|

N/A

>30000 hours

|

|

S1 Continuous Operation Service Life (LH)

|

N/A

>15000 hours

|

|

Efficiency (η)

|

N/A

≥ 97 %

|

|

Operating Temperature

|

N/A

-25 to +90 ºC

|

|

Lubrication

|

N/A

Synthetic Grease

|

|

Protection Class

|

N/A

Ingress Protection (IP65)

|

|

Mounting Position

|

N/A

Any

|

|

Noise Level

|

N/A

≤ 56 dB

|

|

Weight

|

N/A

0.7 kg

|

|

Weight Tolerance (±)

|

N/A

3 %

|

|

Mass Moments of Inertia

|

N/A

0.03 kg·cm²

|

|

Features

|

N/A

One-Piece Gearbox Housing

The gearbox and internal ring gear are a one-piece construction. High gear accuracy meets DIN6 class.

Full Needle Roller Bearings Design

The planetary gear transmission employs full needle roller bearings without a retainer to increase the contact surface that maximizes structural rigidity and service life.

Collet Locking Mechanism

The input-end and the motor are coupled through a collet locking mechanism that ensures concentricity and balance on the connection and no backlash for power transmission while running at high speed.

Integrated Planetary Arm Bracket

The planetary arm bracket and the output shaft are one-piece constructed to increase torsional rigidity and accuracy. The entire structure is machined for controlling accuracy in the specified tolerance.

|